4 min read

In Nepal, the vast majority of villagers cook on open fires for every meal. These fires are smoky and inefficient, but villagers have almost no other option. International NGOs have been trying to introduce improved cookstoves for many years, but the acceptance rate has been very low – Nepalis complain that they don’t fit their needs. The need for a better approach became particularly obvious after the big earthquake of 2015 that destroyed millions of houses and forced hundreds of thousands of villagers to live in tents.

When I set out to create a new kind of wood-burning cookstove, I knew that the project would happen through user-centered design. This kind of design process is iterative: 1) make a design, 2) get user critiques and ideas for improvements, and 3) repeat. When user feedback is overwhelmingly positive, the product is ready for a larger market.

But it’s not as easy as it sounds!

How we started out

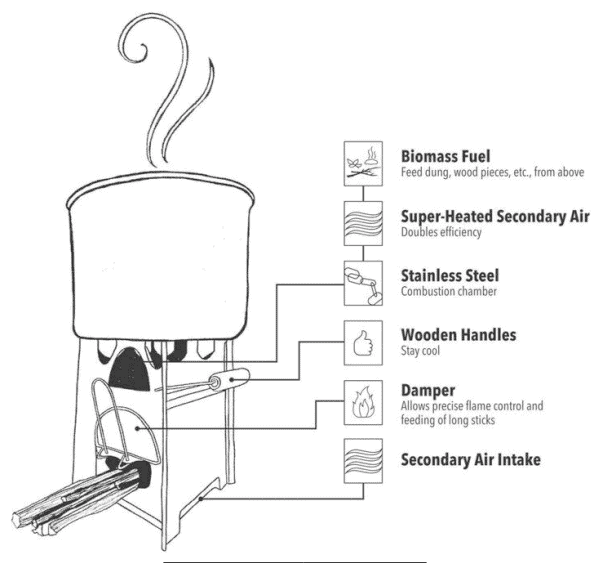

With a team of 4, I put together the best elements of wood-burning backpacking stoves: a double wall that uses secondary air to improve combustion; parts that are joined without tools so the stove can be transported flat; stainless steel that can be heated and cooled thousands of times.

We also wanted it to be easily stamped out of metal sheets, so that production could be inexpensive and rapidly scaled up.

Lesson #1: Make it bigger

The first generation stove was simple, used identical parts repeatedly, and packed flat. In using the stove, however, it became clear that it was too small for anything but backpacking, and required large amounts of small twigs to use.

The next iteration

The second-generation stove fixed all of these problems, and we gave ourselves a pat on our backs with many pots of tea made on the stove!

With 35 stoves produced, we took them to Brabal, Nepal to get the project’s first real-world feedback.

The villagers of Brabal were very kind, and never made a negative comment about the stove. But as we watched them over the course of a week, it soon became clear that the stove would have very limited use in their normal lives.

Lesson #2: Don’t Expect Villagers to Change Their Behavior

The villagers would collect wood an hour or more from their home, and cut the wood in the field to a traditional size that is easiest to carry (average pieces are 3x3x60cm). The Ganesha prototype was too small (note the size of the teapot on the stove above); wood had to be chopped into small pieces to fit into the stove; and wood couldn’t be fed horizontally into the stove.

A further iteration

At this point, a total redesign was called for. While we kept the same design principles, we created a bigger stove that could be fed from the side, with parts that fit together easily to make a very strong, rigid stove.

Stove samples were sent to a testing lab in Kathmandu, with tests showing high efficiency and low emissions. The stove was much better for the environment than the open fires that most Nepalis use, and just as clean as other improved stoves.

Now came the big test: we had to see if Nepalis wanted to cook on it.

Lesson #3: Do Pilot Projects to Get Lots of Real-World Feedback

The first stoves of this generation got excellent reviews from Nepali villagers, so we decided to do a set of pilot projects. Working with NGOs around Nepal, 360 Ganesha stoves were distributed in 6 villages, some as far as 300 km from Kathmandu.

Results: 93% acceptance rate. With the help of NGO partners, we went back to the 6 villages to get feedback. The results were convincing: 93% of villagers said they would buy it (this is a key usability question). The vast majority of villagers said they cooked all of their normal foods on the stove, and the food cooked on the stove was “tasty”. On average, villagers used the Ganesha stove for more than 50% of their cooking, and the longer they owned the stove, the more times per day they used it.

On the tech side, this design kept the key elements: no-tool assembly, easily mass produced, packs flat, rigid and strong, and can use Nepal-normal sized wood as well as dung, corn cobs and other biomass. Lab testing showed this design was the best yet.

What’s Next?

We are now promoting the stove among carbon credit project developers, international NGOs, and Nepali provincial governments. On the design front, we are taking our lessons learnt to create more sizes: one big enough for feeding animals or large groups of people, and one with two cooking spots.

To partner with us, check out our project listing on the Deal Share Platform or reach out to Brice Hoskin, [email protected] if you have any questions.

Many thanks to Ganesha Cookstove Project partners and supporters!